- General

- Specification

- Compliance

- Range

- Installation

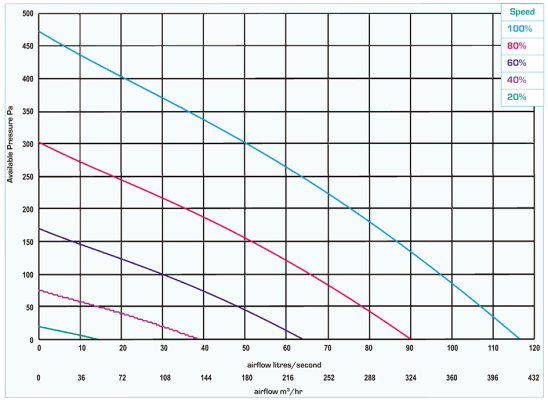

- Pressure

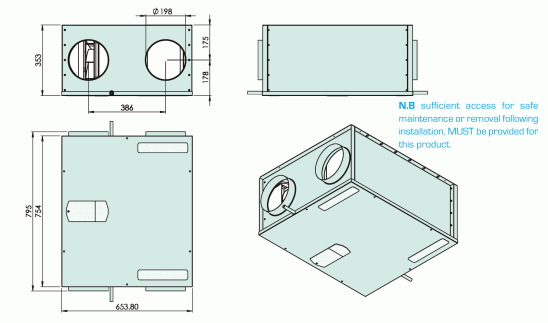

- Dimensions

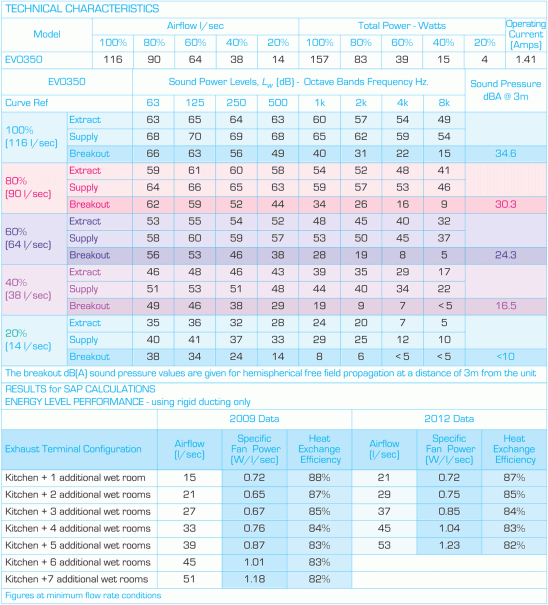

- Data

- Typical specification

- Specification

- Leaflets

- O&M Sheets

- Revit File

- Embodied Carbon Report

- ErP Data

EVO350

- with summer bypass and frost-stat

- efficient, low energy solution to controlling condensation and pollution in residential properties up to 200m²

- up to 88% heat exchange efficiency

- variable choice of low (trickle), boost and purge speed at installation

- for ceiling, loft or void installation

- low noise levels

- low running costs

- complies with Building Regulations

- manufactured in UK to ISO 9001:2015 and 14001:2015

- accurate commissioning via remote LCD commissioning unit

- SAP PCDB Listed

General

- up to 107 litre/sec at 50Pa - max 116 litre/sec capacity

- sfp down to 0.65 W/l/s

- summer bypass which allows the airflow to bypass the heat exchanger automatically when internal and external temperatures are between adjustable setpoints.

- frost-stat - proportionally reduces intake motor speed as temperature falls - activated when the outside temperature between +3ºC and -8ºC.

- run-time and power outage counters

- easy to install and maintain

- for ceiling, loft or void in-line installation

- variable low (trickle), boost and purge options for each motor

- boost speed can be activated by a 230V switched live from:

- A light switch (if more than one light switch is used, each one must be a double pole switch)

- Remote humidistat (230V - DRH240)

- Passive infra red (230V - PIRFF)

- Thermostat (230V - THM)

- Remote switch/pull cord - 230V

- very low noise levels

- low running costs

- 5 year warranty - 1 year parts and labour, 4 years parts only

CONTROL FEATURES - STANDARD

- independent variable speed adjustment for each motor for trickle, boost and purge speeds.

- adjustable boost speed over-run timer from 0 to 30 minutes.

- adjustable boost speed delay from 0 to 5 minutes

- remote purge cable connection on circuit board (for optional purge facility).

- adjustable night time boost and purge inhibitor

- integral frost-stat - proportionally reduces intake motor speed as temperature falls

- automatic summer bypass

CONTROL FEATURES - FACTORY SET

- change of ductwork handing on humidistat version (trip point can be set at manufacture)

- integral humidistat - proportionally increases motor speeds with rising humidity

- 0-10V connections can be added for:

- BMS - for remote motor shut-off

- CO2 detector

- home automation system

- relay for external pre-heater

- 3 speed selector switch

- optional remote purge cable - factory connected - adjustable over-run timer from 0 to 250 minutes, Pre-set to 15 minutes (adjustable at factory)

- holiday mode for reduced speeds when property is unoccupied (factory set option) - default setting is 50% of trickle speed

- run-time and power outage counters downloadable via QR code.

Vectaire Ltd can supply all accessories for use with these units, including product filters, air filter cassettes, silencers, fire dampers, air valves, ducting, outside grilles and wall cowls. Additionally, Vectaire offers a design service to ensure that the unit installed is the best possible to provide efficient, effective, low energy and low running cost ventilation. Vectaire can also organise installation, commissioning and maintenance of these products

Back to top

Specification

- compact low profile unit

- casing from galvanised sheet steel

- thermo-acoustic lining

- pre-wired for easy electrical connection

- low energy EC brushless motor with single width, single inlet, direct drive, backward curved impellors

- operates in temperature up to 60ºC

- easy to access standard, disposable G3 filters

- counter flow heat exchanger

- all models bottom access only

Back to top

Compliance

- Building Regulations for enhanced energy saving capability

- Building Regulations for reliable, efficient ventilation

- EU RoHS Directive Compliant.

- Complies with IEC60335-2-80, LVD2006/95/CE and EMC2014/30/UE (European Directive against radio interference and electro-magnetic compatibility

- manufactured in UK to ISO 9001:2015 and 14001:2015

- CE marked

- SAP PCDB Listed

Back to top

Range

- EVO350DC/BABY - bottom access,ypass

- EVO350DC/BALBYH - bottom access, left drain, bypass, humidistat

- EVO350DC/BARBYH - bottom access, right drain, bypass, humidistat

- EVO350DCF - set of filters for above

Back to top

Typical specification

- The unit will:

- be manufactured by Vectaire Ltd.

- be constructed from galvanised steel sheet and have thermo-acoustic lining to ensure extremely low noise levels

- be suitable for installation in-line in ceilings, voids or lofts

- have drain connections for connection by others.

- have a high efficiency counterflow heat exchanger with a thermal efficiency of up to 88%.

- have two low energy, high efficiency EC fan motor assemblies.

- have a specific fan power from 0.67 W/l/s.

- have G3 grade filters to protect the heat exchanger.

- have an automatic summer bypass

- have an integral frost-stat

- Access to filters shall be from the bottom by removing two magnetic strips

- The unit shall incorporate the following control features:

STANDARD

- independent variable speed adjustment for each motor for trickle, boost and purge speeds.

- adjustable boost speed over-run timer from 0 to 90 minutes.

- adjustable boost speed delay from 0 to 5 minutes

- remote purge cable connection on circuit board (for optional purge facility)

- adjustable night time boost and purge inhibitor

- integral frost-stat - proportionally reduces intake motor speed as temperature falls

- summer bypass - automatic bypass of heat exchanger in hot weather

FACTORY SET

- change of ductwork handing on humidistat version (trip point can be set at manufacture)

- integral humidistat - proportionally increases motor speeds with rising humidity

- 0-10V connections can be added for:

- BMS - for remote motor shut-off

- CO2 detector

- home automation system

- external pre-heater

- 3 speed selector switch

- optional remote purge cable - factory connected - adjustable over-run timer from 0 to 250 minutes, Pre-set to 15 minutes (adjustable at factory)

- holiday mode for reduced speeds when property is unoccupied (factory set option)

- run -time and power outage counters downloadable via QR code.

- Remote (optional) LCD touch screen informs user of:

- operating speed (user adjustable)

- internal and external temperatures

- status icons shows which functions currently controlling fan speed

- date and time (user adjustable)

- relative humidity level

- bypass status

- error and service notifications

- filter saturation level (reset after changing)

- user can also set system to holiday mode and set language

- An LCD Commissioning Kit will allow the commissioning engineer or installer to set the following parameters:

- Time and Date

- Holiday Mode

- Trickle, boost and purge speeds for each motor

- Boost speed delay time duration

- Boost over-run time duration

- Night time boost inhibitor times

- Touch screen sensitivity calibration

- Pre-heater threshold (if fitted)

- Handed installations

- Activate CO2 detector or home automation system (if fitted)

- The unit will:

- be CE marked

- comply with:

- manufactured in UK to ISO 9001:2015 and 14001:2015

- be SAP PCDB Listed

- have a 5 year warranty -1 year parts and

- Building Regulations for enhanced energy saving capability

- Building Regulations for reliable, efficient ventilation

- EU RoHS Directive Compliant

- IEC60335-2-80, LVD2006/95/CE and EMC2014/30/UE (European Directive against radio interference and electro-magnetic compatibility

labour and 4 years parts only

Back to top

Download

Download Download

Download Download

Download