- General

- Specification

- Compliance

- Range

- Installation

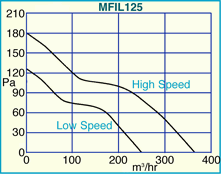

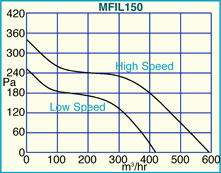

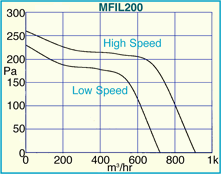

- Pressure

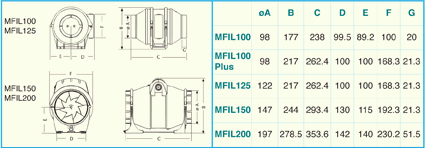

- Dimensions

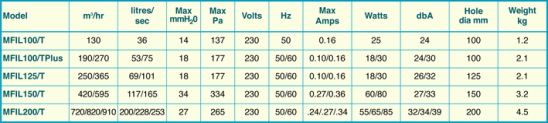

- Data

- Accessories

- Typical specification

- Leaflets

"MFIL" - in-line centrifugal

- Centrifugal fans for domestic or commercial use

- 6 models

- 4 sizes

- 2 timer models

- 5 models with 2 speed motor

- 1 model with 3 speed motor

- IPX4 - Splashproof

- Exceeds Building Regulations requirements

General

- centrifugal in-line fans for domestic or commercial use

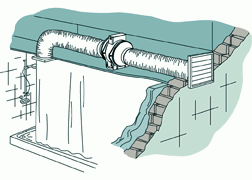

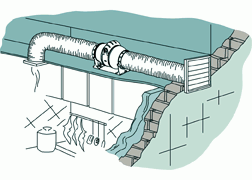

- easy to install and maintain - fan can be accessed without removing ducting

- can be used with flexible or rigid ducting

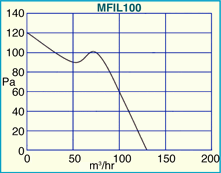

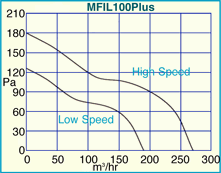

- high performance extract capacities and pressures

- two and three speed motors on fans allow for selection of required speed on installation

- MFIL150 and MFIL200 can be used with speed controller

- low noise levels

- suitable for continuous running

- timer adjustable from 3-15 minutes

- IPX4 - Splashproof - can safely be installed in Zones I and II

Back to top

Specification

- made of shock proof and heat resistant plastics

- double insulated motors of shaded pole type on self-lubricating, sealed ball bearings for long life

- motor windings protected to Class B

- motors incorporate thermal cut-out

- maximum ambient temperature 40°C

Back to top

Compliance

- The Ecodesign for Energy-Related Products and Energy Information (Amendment) EU Exit) Regulations 2019.

- The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012;

- Electromagnetic Compatibility Regulations 2016,

- Electrical Equipment (Safety) Regulations 2016

- UKCA andCE marked

Back to top

Range

- MFIL100-Plus - with 2-speed motor

- MFIL100T-Plus - with timer and 2-speed motor

- MFIL125 - with 2-speed motor

- MFIL125T - with timer and 2-speed motor

- MFIL150 - with 2-speed motor

- MFIL200 - with 3-speed motor

Back to top

Typical specification

Supply and install a Vectaire MFIL125T in-line centrifugal fan suitable for either domestic or commercial use as supplied by Vectaire Ltd, Lincoln Road, Cressex Business Park, High Wycombe, Bucks, HP12 3RH. The fan should be capable of being ducted over long lengths of either rigid or flexible ducting and should have an over-run timer, which is adjustable from between 3 and 15 minutes. The fan should be made of shockproof and heat resistant plastic, contain a two-speed motor with sealed, self-lubricating bearings, and be protected with a thermal cut-out. It should be possible for the installer to select the desired operating speed when fitting. The fan should be double insulated, be splashproof to IPX4 making it suitable for installation into Zones I and II and comply with all current IEE, EC and Building Regulations requirements.

Back to top

Bathroom

Bathroom Kitchen

Kitchen

Fixed Grille

Fixed Grille Gravity Grille

Gravity Grille Flexible Ducting

Flexible Ducting Download

Download