- General

- Specification

- Compliance

- Range

- Features

- Installation

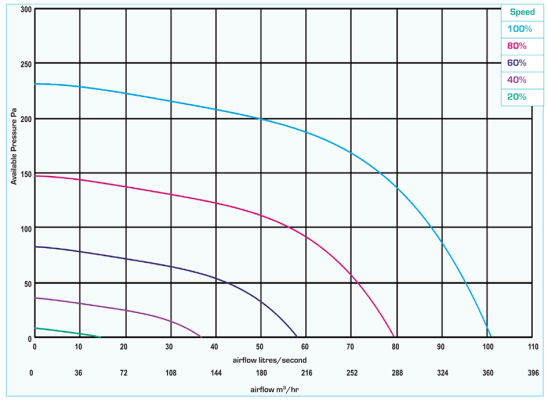

- Pressure

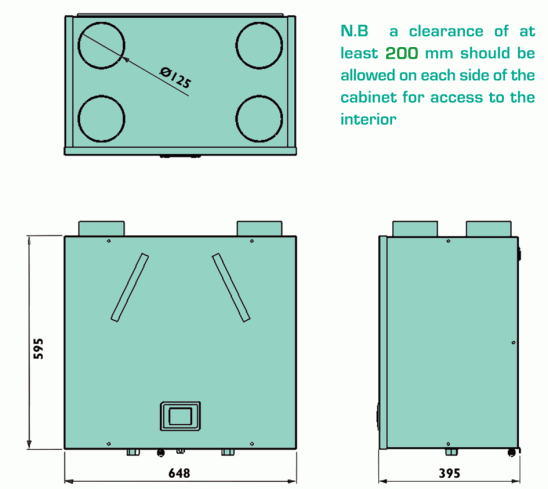

- Dimensions

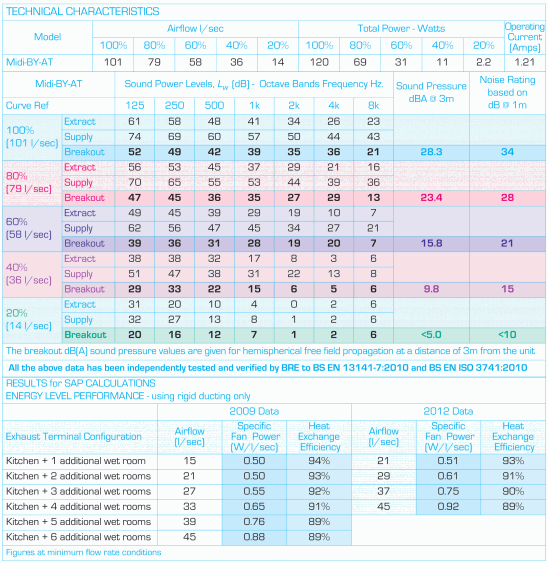

- Data

- Typical specification

- Specification

- Leaflets

- O&M Sheets

- Revit File

- Embodied Carbon Report

- ErP Data

Midi BY AT

- very low noise levels - tested by BRE

- lined with Class "O" fire resistant acoustic foam

- with summer bypass and frost protection

- efficient, low energy solution to controlling condensation and pollution in residential properties up to 170m2

- up to 94% heat exchange efficiency

- variable choice of low (trickle), boost and purge speed at installation

- for wall, cupboard or loft installation

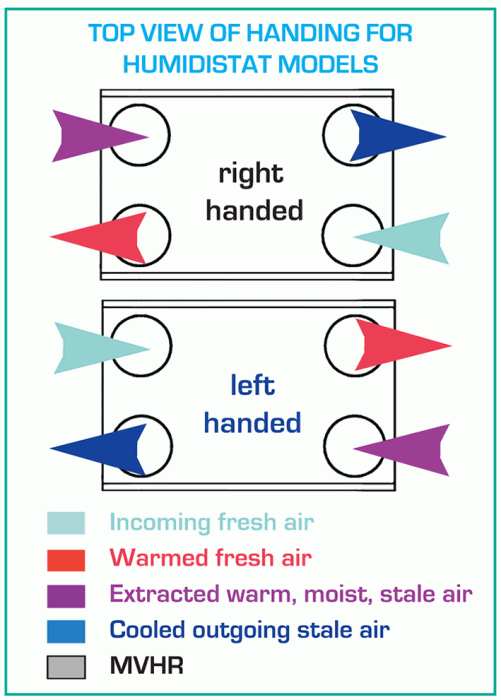

- universal handing for models without humidistat

- low running costs

- complies with Building Regulations

- manufactured in UK to ISO 9001:2015 and 14001:2015

- accurate commissioning via integral touch screen LCD

- SAP PCDB Listed

General

- extremely low noise levels

- up to 95 litre/sec at 50Pa - max 101 litre/sec capacity

- sfp down to 0.50 W/l/s

- summer bypass which allows the two airflows to bypass the heat exchanger automatically when internal and external temperatures are between adjustable setpoints.

- frost-stat - proportionally reduces intake motor speed as temperature falls - activated when the outside temperature between +3ºC and -8ºC.

- run-time and power outage counters

- easy to install and maintain

- easy to access G3 filters

- universal handing for models without humidistat - left or right

- for fitting vertically into lofts, or cupboards - wall fixing bracket supplied

- variable low (trickle), boost and purge options for each motor

- boost speed can be activated by a 230V switched live, or a 0-10V connection from:

- a light switch (if more than one light switch is used, each one must be a double pole switch)

- Remote humidistat (230V - DRH240)

- Passive infra red (230V - PIRFF)

- Thermostat (230V - THM)

- Remote switch/pull cord - 230V

- low running costs

- 5 year warranty - 1 year parts and labour, 4 years parts only

CONTROL FEATURES - STANDARD

- independent variable speed adjustment for each motor for trickle, boost and purge speeds.

- adjustable boost speed over-run timer from 0 to 30 minutes.

- adjustable boost speed delay from 0 to 5 minutes.

- remote purge cable connection on circuit board (for optional purge facility)

- adjustable night time boost and purge inhibitor.

- integral frost-stat - proportionally reduces intake motor speed as temperature falls

- automatic summer bypass

CONTROL FEATURES - FACTORY SET

- change of ductwork handing on humidistat version (trip point can be set at manufacture)

- integral humidistat - proportionally increases motor speeds with rising humidity

- 0-10V connections can be added for:

- BMS - for remote motor shut-off

- CO2 detector

- home automation system

- relay for external pre-heater

- 3 speed selector switch

- optional remote purge cable - factory connected - adjustable over-run timer from 0 to 250 minutes, Pre-set to 15 minutes (adjustable at factory)

- holiday mode for reduced speeds when property is unoccupied (factory set option)

- run-time and power outage counters downloadable via QR code

Back to top

Specification

- compact unit - casing from steel sheet - epoxy paint finish

- lined with Class "O: fire resistant acoustic foam

- low energy EC brushless motor with single width, single inlet, direct drive, forward curved impellors

- operates in temperature up to 60ºC

- easy to access standard, disposable G3 filters

- counter flow heat exchanger

Back to top

Compliance

- Building Regulations for enhanced energy saving capability

- Building Regulations for reliable, efficient ventilation

- EU RoHS Directive Compliant.

- Complies with IEC60335-2-80, LVD2006/95/CE and EMC2014/30/UE (European Directive against radio interference and electro-magnetic compatibility

- manufactured in UK to ISO 9001:2015 and 14001:2015

- CE marked

- SAP PCDB Listed

Back to top

Range

- Midi BY-AT - bypass, attenuation, universal, integral LCD

- Midi BYATH/LH - bypass, attenuation, humidistat, left drain, integral LCD

- Midi BYATH/RH - bypass, attenuation, humidistat, right drain, integral LCD

- MIDI-AT-F - set of filters for above models

Back to top

Typical specification

- The unit will:

- be manufactured by Vectaire Ltd.

- be constructed from steel sheet with an epoxy paint finish and the case lined and insulated with Class "O" fire resistant acoustic foam to ensure extremely low noise levels.

- be suitable for installation on walls, in cupboards or in lofts.

- have a condensate tray and drain connections for connection by others.

- have a high efficiency counterflow heat exchanger with a thermal efficiency of up to 94%

- have two low energy, high efficiency EC fan motor assemblies.

- have a specific fan power from 0.50 W/l/s.

- have two G3 grade filters to protect the heat exchanger

- will operate in temperature up to 60ºC

- have an automatic summer bypass

- have an integral frost-stat

- Units without humidistats shall be capable of being handed for left or right mounting without any on-site assembly.

- Access to filters shall be from the front by removing two magnetic strips.

- The unit shall incorporate the following control features:

STANDARD

- independent variable speed adjustment for each motor for trickle, boost and purge speeds.

- adjustable boost speed over-run timer from 0 to 30 minutes.

- adjustable boost speed delay from 0 to 5 minutes

- remote purge cable connection on circuit board (for optional purge facility)

- adjustable night time boost and purge inhibitor

- integral frost-stat - proportionally reduces intake motor speed as temperature falls

- summer bypass - automatic bypass of heat exchanger in hot weather

FACTORY SET

- change of ductwork handing on humidistat version (trip point can be set at manufacture)

- integral humidistat - proportionally increases motor speeds with rising humidity

- 0-10V connections can be added for:

- BMS - for remote motor shut-off

- CO2 detector

- home automation system

- external pre-heater

- 3 speed selector switch

- optional remote purge cable - factory connected - adjustable over-run timer from 0 to 250 minutes. Pre-set to 15 minutes (adjustable at factory)

- holiday mode for reduced speeds when property is unoccupied (factory set option)

- run-time and power outage counters downloadable via QR code.

- LCD touch screen informs user of:

- operating speed (user adjustable)

- internal and external temperatures

- status icons shows which functions currently controlling fan speed

- date and time (user adjustable)

- relative humidity level

- bypass status

- error and service notifications

- filter saturation level (reset after changing)

- user can also set system to holiday mode and set language

- (Loft mounted units can be provided with a remote LCD touch screen).

- The LCD touch screen will allow the commissioning engineer or installer to set the following parameters:

- Time and Date

- Holiday Mode

- Trickle, boost and purge speeds for each motor

- Boost speed delay time duration

- Boost over-run time duration

- Night time boost inhibitor times

- Touch screen sensitivity calibration

- Pre-heater threshold (if fitted)

- Handed installations

- Activate CO2 detector or home automation system (if fitted)

- The unit will:

- be CE marked

- comply with:

- manufactured in UK to ISO 9001:2015 and 14001:2015

- be SAP PCDB Listed

- have a 5 year warranty -1 year parts and labour and 4 years parts only

- Building Regulations for enhanced energy saving capability

- Building Regulations for reliable, efficient ventilation

- EU RoHS Directive Compliant

- IEC60335-2-80, LVD2006/95/CE and EMC2014/30/UE (European Directive against radio interference and electro-magnetic compatibility

Back to top

Download

Download Download

Download Download

Download