STP STR

- STP and STR - Internal and External Air Handling and Heat Recovery Units

- Model are available as side by side or stacked layouts

- The STP/STR range of air handling units is available in 25mm or 50mm construction.

- 11 modular sizes up to 14m3/sec air volume.

- Custom made sizes up to 20m3/sec air volume.

- Non-standard sizes for enhanced versatility.

- Enhanced specification to HTM or coastal environments.

- Units incorporate high quality components sourced through our market leading supply chain partners.

- Flat pack service available

- All models ErP Compliant and manufactured in the UK to ISO9001

General

Enjoy a comfortable, healthy environment with our extensive range of easy-to-use air handling units. Custom made units are able to deliver up to 20m3/sec through a non-intrusive system. High efficiency heat recovery options ensure no loss of heat while still delivering a constant flow of fresh air into your building.

- Larger sizes for plant and external installation

- With electric or LPHW heater batteries

- 11 modular sizes, airflow to 14 m³/sec.. Custom Built sizes up to 20m3/sec air volume

- Wide selection of control panels available

- Enhanced specification to HTM or coastal environments

- Robust extruded aluminium tubular frame 30mm x 30mm (for 25mm construction) or 30mm x 50mm for 50mm construction.

- Unit panels from double skinned galvanised steel

- Steel channel base running full length of unit with cross members at suitable locations.

- Filter and access panels fitted with easy access fasteners – other removable panels retained via roofing bolts.

- External models outer skin with plastic coated finish (Grey to BS10A05) as standard.

- Weatherproof pitched lid fitted on external models

- External models air inlet/exhaust air discharge via weather cowl as standard. Weather louvres available. All fitted with birdmesh guard

- 25mm and 50mm thick panels with 45 kg/m3 density mineral wool insulation as standard. (Aternative options available for lower sound level requirements)

- Variable control packages - loose or factory fitted Can be customised to offer:

- temperature and humidity control to ensure space conditions are maintained.

- demand ventilation control to maximise energy performance.

- user interfacing to suit individual applications.

- extensive connectivity - building integration via various protocols including BACnet®, Modbus® and TREND®.

- Sensors, Silencers and Filter Boxes available

Back to top

Specification

- Backward curved direct drive plug style impellers

- Fan impellers are statically and dynamically balanced in accordance with ISO 14694 and ISO 1940/1. Supplied as standard with pre-greased sealed for life bearings having L10 life of 20,000 hours at peak performance

- Fan motors pre-wired to inverter and isolator

- Standard motors of squirrel cage induction type, totally enclosed, fan cooled, suitable for 3ph, 50Hz electricity supply, IE2

- Motors with IP55 protection and Class F rating

- High efficiency EC motors available as an option, depending on duty requirement

- Fan and motor are mounted on a common chassis frame isolated from casing via rubber anti-vibration mounts and flexible connector fitted to fan inlet. Transit bolt fitted to prevent damage during transport

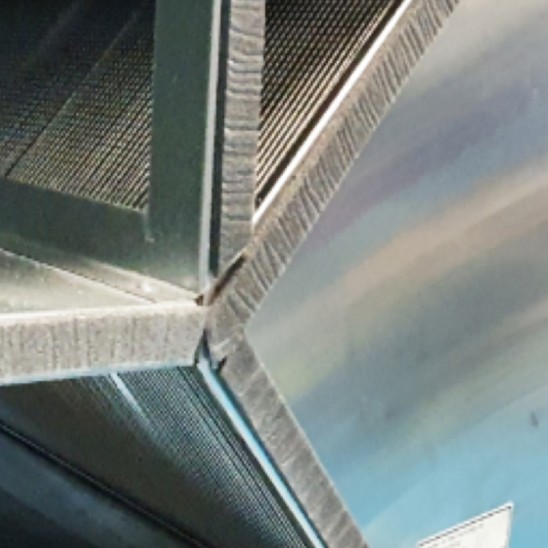

- LPHW batteries are constructed from copper tubes mechanically bonded onto aluminium fins supplied with standard BSP male connectors. Option of vinyl coating (copper and electro-tinned copper also available). The coil casing is in galvanised sheet steel

- Drain tray and moisture eliminator plates manufactured from polypropylene fitted as standard to cooling coils. Coils are mounted on slide-in channels to aid removal

- Electric heater batteries for single and 3 phase operation are manufactured from sheathed rod elements with an integral manual reset thermal cut-out for wiring into control unit. It is recommended that fan run-on timer is incorporated in controls to prevent possible heat damage

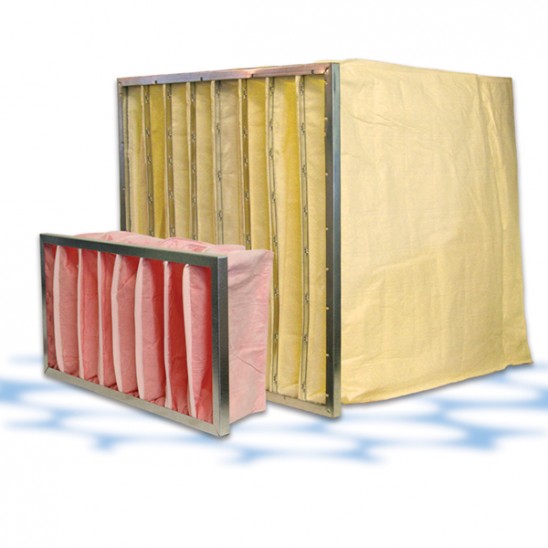

- Panel filters to G4 grade mounted in slide-in channels. Bag filters of F6 and above are mounted in purpose made front withdrawal holding frames and retained by spring loaded clips

- Intake dampers of opposed blade, multi-leaf type fitted aerofoil section blades. Extended shaft for fitting of suitable motor is provided as standard

- Attenuators manufactured with galvanised sheet steel case fitted with "Mez" type flange at each end.

Back to top

Range

STP/STR1 STP/STR2 STP/STR3 STP/STR4 STP/STR5 STP/STR6 STP/STR7 STP/STR8 STP/STR9 STP/STR10 STP/STR11

11 standard sizes with air volume to 14m 3/sec Bespoke models with air volume to 20 m3/sec

Back to top

Filters

Filters Control

Control Attenuation

Attenuation Plate Heat Exchanger

Plate Heat Exchanger Selection Chart

Selection Chart Download

Download